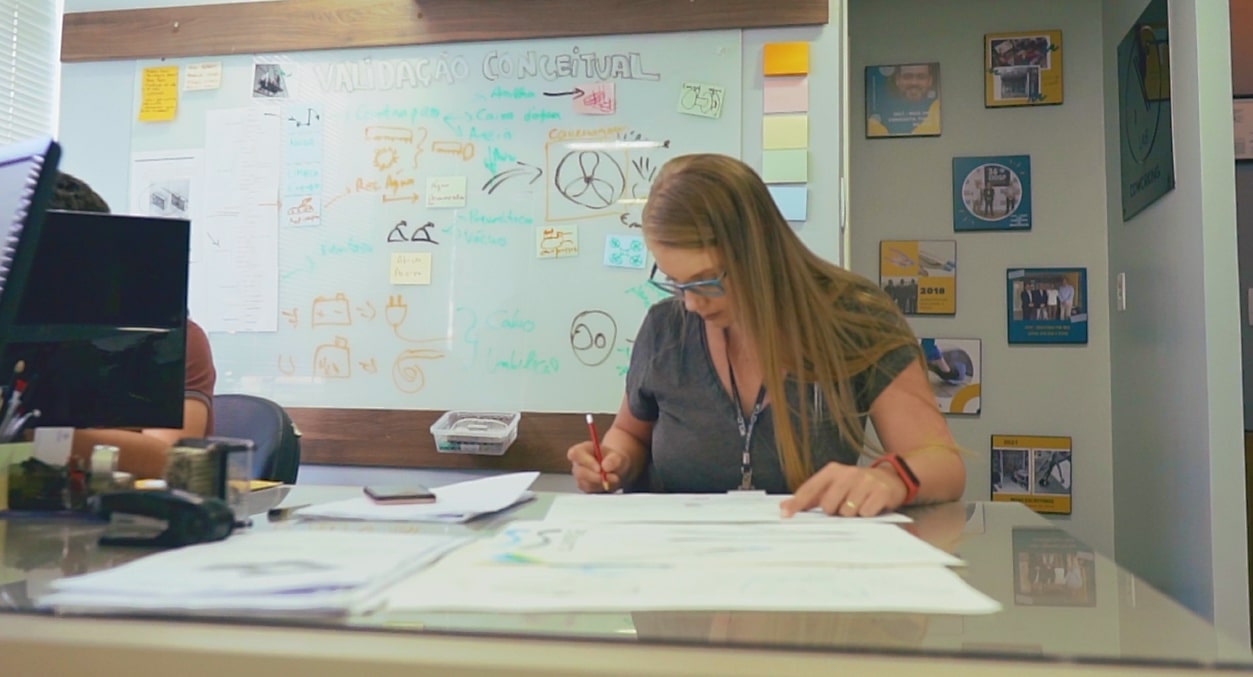

CONCEPT VALIDATION

Every great solution starts with a problem. At DUO, we work on risk reduction projects at each step. And one of the biggest risks of developing a new product is to approach a problem in a wrong way. In order to avoid this, the approaching cycle should be focused on the market.

PROBLEM

Finding / problem validation.

Our goal at stage 1 is to test our assumptions around the problem we find out. Figuring out the cost to the solution of this problem in advance may direct to different kinds of solution alternatives.

SOLUTION

Finding / solution validation.

If the problem is validated we will focus on validating the solution. We will come up with visual representation of the product that in turn we will share with our potential customers in this phase

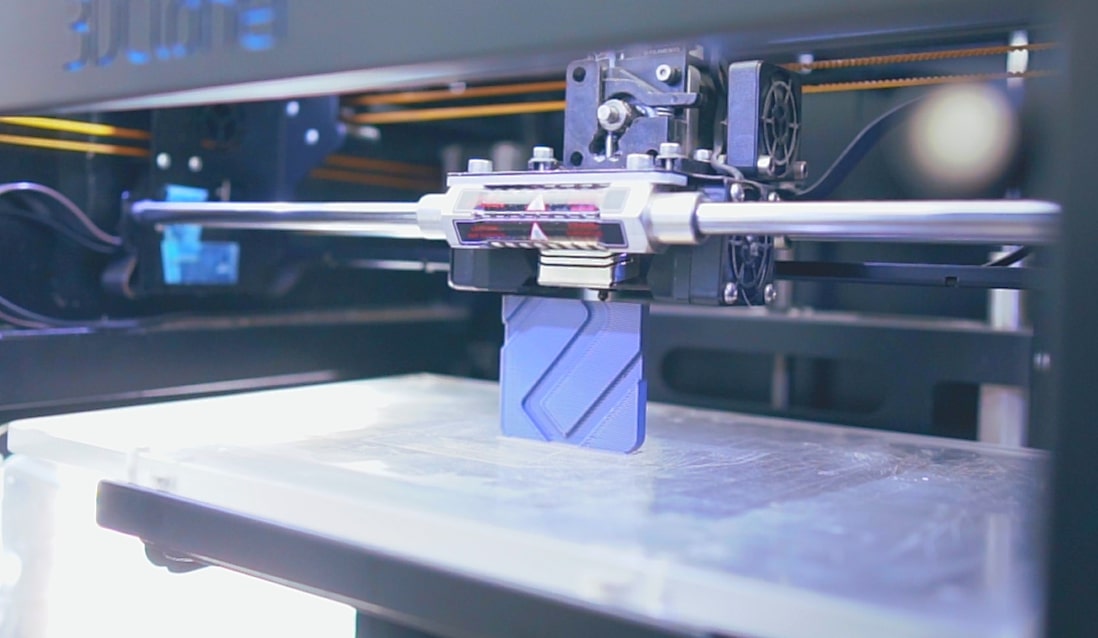

PROTOTYPING

What type of prototype does your project need? Prototyping is much more than printing a part in 3D, you need to have a goal, a learning curve and a structure for this.

The faster and sooner prototypes are made and tested the better for product understanding and development.

FAST PROTOTYPE

Our in-house rapid prototype workshop is equipped with 3D printing machines, enabling quick turnaround of prototype parts.

We prototype parts and components throughout the product development process to assess their fit, form and function. The prototyping technique we use depends on the quality, timing and functional requirements of the part.

INTERACTIVE MVP

Building a minimal viable product (MVP) helps test the user experience early in the product development process. Our team of designers and engineers build creative ways to prototype your interactive product idea early in development.

This allows you to quickly get user feedback and refine functionality, saving development time and costs throughout your project.

DESIGN & ENGINEERING

Our industrial design team works together with our product engineers to develop great design concepts that can be manufactured and meet the needs of your business. Here, we work to bring about a balance between shape and functionality aiming at simplicity.

IDEATION

Starting with your product vision, we work together with you to identify the persona and explore visual concepts to potential solutions though sketches. After we come up with a direction to go to, the team develops attractive design models and integrates these concept ideas with a practical and viable engineering architectures. The final concepts of the project are drawn at CAD 3D so that they can be evaluated by the customers, users and stakeholders.

MECHANICAL ENGINEERING

This is our main expertise! Functional products require an excellent mechanical engineering. Our team of interdisciplinary designers are experienced in making products work, and work well, may they be mechanisms, machines, devices we are focused on developing functions that make products useful, intuitive and user-friendly.

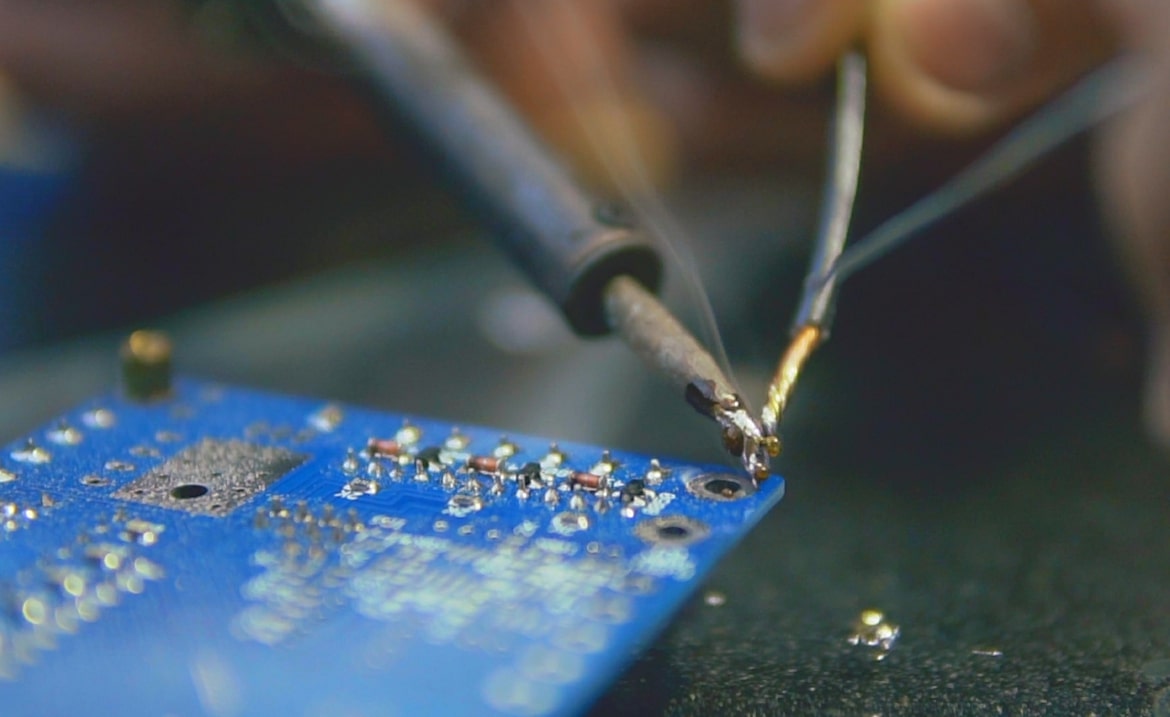

ELETRONIC ENGINEERING

We have vast experience in automation and electronic engineering, systematic architecture, schematic design, board layout, prototyping and firmware development.

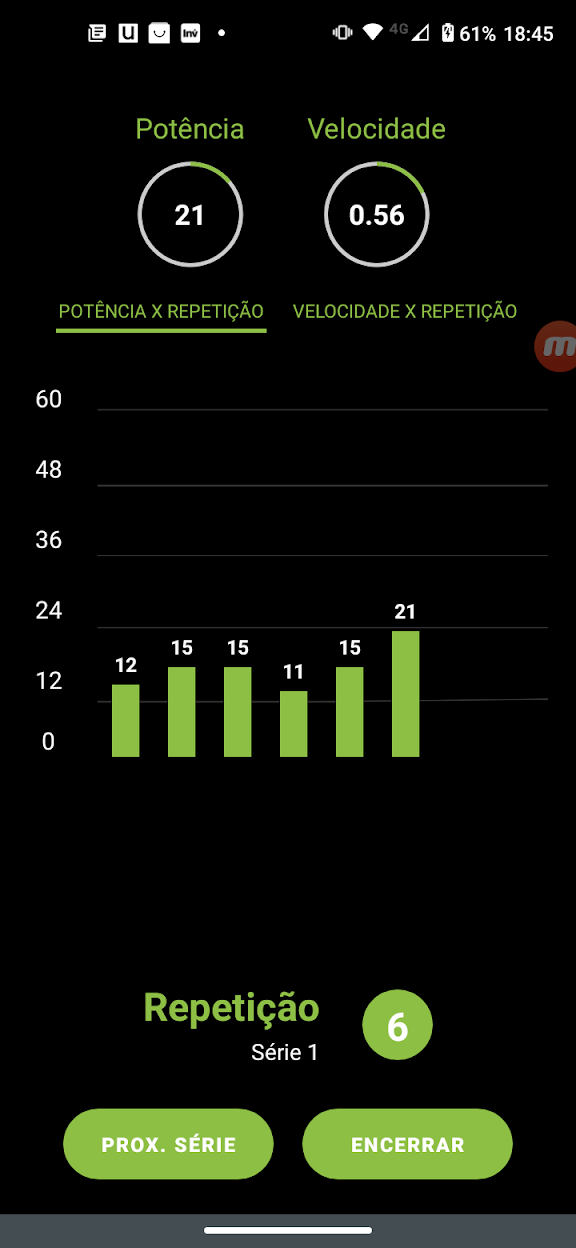

SOFTWARE ENGINEERING

We offer a complete team for product development, if you product needs software we have the right solution for you, offering an excellent UX/UI as well as the software programing to make sure the product design meets the needs of the user.

MANUFACTURE

Once your concept or design has been proven through prototypes, and we've fully mapped the production process, your design is ready to move to manufacturing. This post MVP phase we call “Product Engineering” and covers other topics not covered in the R&D phase.

BILL OF MATERIALS (BOM)

The Bill of Materials is a list of raw materials needed to assemble the product and a comprehensive list of parts, items, assemblies and sub-assemblies, which can be understood as the recipe and shopping list for creating a final product.

INITIAL PRODUCTION PLANNING

The best solutions start with manufacturing knowledge built into the early design concept stage, where it matters most. At the beginning of your project, you will work with a team of experts who will consider manufacturing to get the initial cost of key items and start looking for the best partners for your project.

PRODUCTION DOCUMENTATION

We offer manufacturing specification drawing packages, detailed part drawings and assembly schematics, communication and production support according to your product and production tooling details.